Detailed introduction:

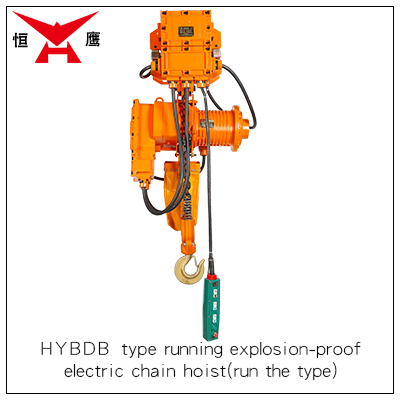

1. Suitable headroom height can increase the lifting height by 200~500mm compared with ordinary CD hoist.

2. Excellent three-in-one transmission technology, the lifting reducer is made of high-quality alloy steel, three-stage reduction, stable operation, long life, reliable performance, avoiding many shortcomings of CD hoist intermediate shaft long-distance transmission.

3. The motor is a specially designed new self-cooling cone motor. The motor shell is made of aluminum alloy with good heat dissipation performance. The motor insulation class is F class and the protection class is IP54, which is one level higher than normal motors.

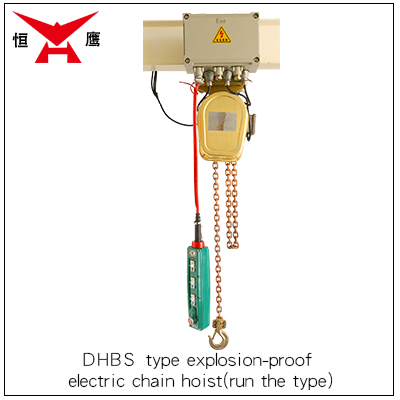

4. The electrical components are Schneider products, using large-capacity contactors and other components. The connection between the control switch and the motor and electrical components uses quick plugs to make on-site installation faster; each leakage part of the hoist is protected by PE corrugated pipes to ensure the cable Reliable connection.

5. It can be implemented according to user requirements: hoist operation, lifting single and double speed or variable frequency stepless speed control, remote control operation, overload protection, motor overheat protection and other functions.

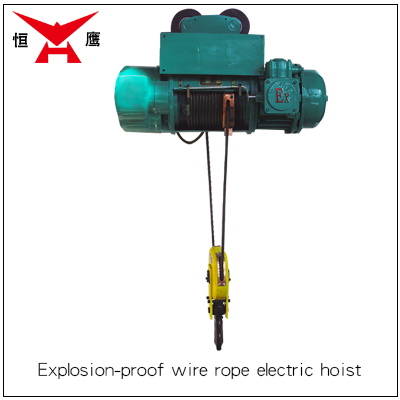

6. Exquisite structure, beautiful appearance, and has many unique advantages:

(1) The main body of the gourd has no leakage cables, and all cables are arranged inside the gourd by various means to make the gourd appearance more beautiful; for example: the support shaft is a hollow thick-walled steel pipe, under the premise of ensuring the strength of use, The overall weight of the electric hoist is reduced, and the cables of the left and right parts of the hoist can be traversed through it.

(2) The structure of the hoist is compact, and the counterweight is a counterweight box type. Users can add various scrap steel or stones, etc., which saves steel, and at the same time reduces the appearance size of the counterweight type low headroom electric hoist;

(3) The hoist is driven by the NF series helical gear reducer. The drive wheels on both sides transmit torque through a six-sided steel. The transmission torque is large and the reliability is high. The shear failure of the flat key is avoided. Very conducive to the installation and adjustment of the running part of the hoist;

(4) The outer cover of the hoisting main unit is a square welded structure with mounting bolt holes on all sides. It has high versatility. It can be quickly changed to a fixed or suspended trolley-operated electric hoist, and the rope can be pulled out in a 360° direction.

7. The whole structure is easy to disassemble and install, easy to overhaul and good maintainability.