Using the information

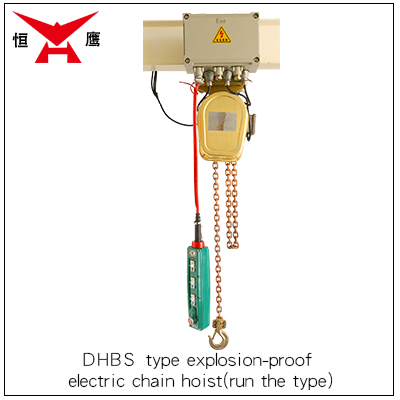

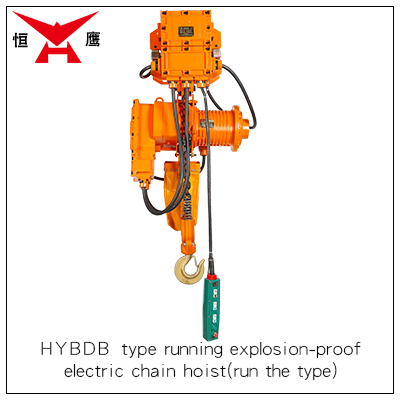

1 for new equipment or equipment disassembly inspection explosion-proof electric hoist, first of all to carry out several air trial operation. Explosion-proof electric hoist the exposed explosion-proof parts of the hoist are made of special non-spark materials, and the explosion-proof performance is safe and reliable. Products through the ministry of machinery industry explosion-proof electrical products quality supervision and inspection center Jiamusi sub-center explosion-proof performance testing, and issued explosion-proof certificate. However, do not run the power test until the equipment is complete. Explosion-proof electric hoist the exposed explosion-proof parts of the hoist are made of special non-spark materials, and the explosion-proof performance is safe and reliable. Products through the ministry of machinery industry explosion-proof electrical products quality supervision and inspection center Jiamusi sub-center explosion-proof performance testing, and issued explosion-proof certificate.

2. Before normal development and application, it is necessary to carry out a static load experiment with 125% of the extra working load, lifting height about 100mm above the ground, and test the system for 10 minutes to check whether it can be normal. Explosion-proof electric hoist the exposed explosion-proof parts of the hoist are made of special non-spark materials, and the explosion-proof performance is safe and reliable. Products through the ministry of machinery industry explosion-proof electrical products quality supervision and inspection center Jiamusi sub-center explosion-proof performance testing, and issued explosion-proof certificate.

In figure 3. Dynamic load test is a repeated lifting and moving test with additional load components. After the experiment, check whether the mechanical transmission part, electrical part and connection part are normal and stable.

4. When used, it must be prohibited to use in the environment that is not allowed, and exceed the extra load and additional closing times per hour (120 times).

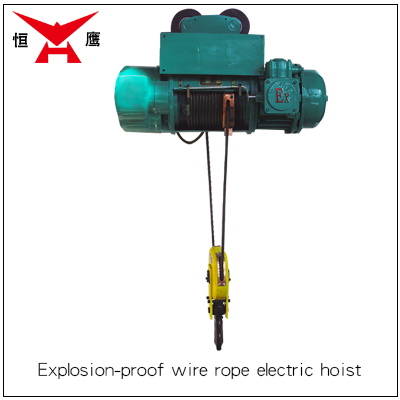

5. Equipment in the system debugging and protection, we must carefully analyze to see whether all limit control equipment management can be flexible and reliable, when the hook quality rises to a limit of the direction, the distance between the hook shell and drum shell design should be greater than 50mm(10T, 16T, 20T must choose greater than 120mm). When the hook drops to the lower limit azimuth, it is necessary to ensure that the safety ring of the wire rope on the reel is improved, and the safety ring of useful information is necessary to be more than 2 laps.

6. It is not allowed to press the two flashlight door buttons that make the explosion-proof electric hoist move in opposite directions at the same time.

Cut it off. When you're done, make sure you cut the main power. Cut the power.

8. Explosion-proof electric hoist should be operated by professionals, and operators should fully master the safety operation rules to prevent tilting and slant.

9. In operation, special researchers must regularly check the information of explosion-proof electric hoist. If we find defects, we should analyze them in a timely and effective manner, and record them carefully.

Figure 10. Explosion-proof electric hoist when adjusting the brake slider, should ensure that under the action of additional load, SV /100(V is the distance of stable rise within one minute under the action of load) of the brake slider.

11. Wire rope failure specification: The inspection and failure specification of wire rope shall be implemented in accordance with CB/T5972-1986 "Practical Specification for Inspection and Failure of Wire Rope for Hoisting Machinery".

12 explosion-proof electric hoist in the use of teaching must use a suitable lubricating oil, and to ensure that the lubricating oil is clean, should not be used containing a lot of impurities and dirt.

13. When oiling the wire rope, use a brush or wood block to prevent the wire rope from being oiled directly by hand.

Explosion-proof electric hoist can not be suspended in the air when it is not working to avoid permanent deformation of components.

15. In the process of application, if any defect is found, the main power supply should be cut off immediately.

16. In the application of teaching process management, special attention should be paid to the situation of wearing parts.

17.10 ~ 20 ton hoist may cause active power outage after continuous operation for a long time. This is due to the overheating protection function of the motor. At this time, it must immediately descend and wait for a period of time. After the motor cools down, it can continue to work.