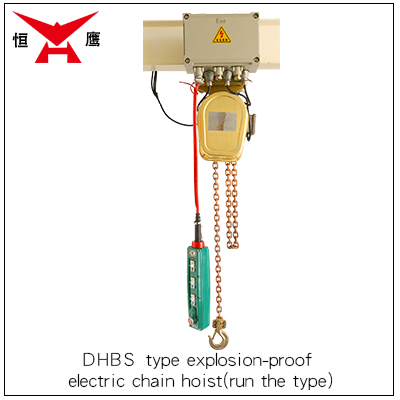

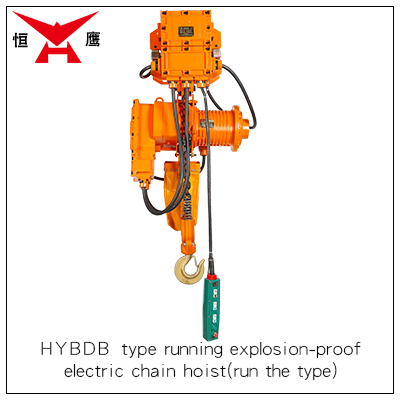

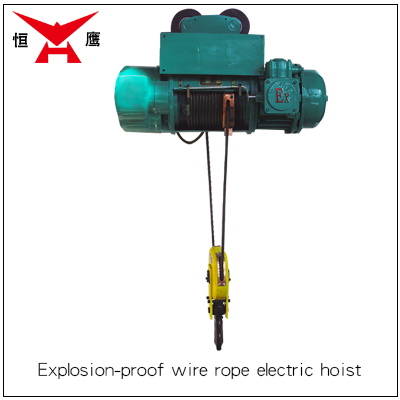

For the enterprise explosion-proof electric hoist we learn is not completely strange, but because of the specific management of explosion-proof electric hoist basic principle is what, the development process of the whole social work is what? Lifting equipment as a professional knowledge of production technology manufacturers to give you high quality students answer. Explosion-proof electric hoist the exposed explosion-proof parts of the hoist are made of special non-spark materials, and the explosion-proof performance is safe and reliable. Products through the ministry of machinery industry explosion-proof electrical products quality supervision and inspection center Jiamusi sub-center explosion-proof performance testing, and issued explosion-proof certificate. When the outer mold climbs, it climbs upward by means of jacks standing on the concrete wall. Explosion-proof electric hoist the exposed explosion-proof parts of the hoist are made of special non-spark materials, and the explosion-proof performance is safe and reliable. Products through the ministry of machinery industry explosion-proof electrical products quality supervision and inspection center Jiamusi sub-center explosion-proof performance testing, and issued explosion-proof certificate. Climb template can leave concrete building metope is 200-300 - mm, not economic friction resistance after climb to elevation, external formwork frame bracket into concrete reserved hole inside the wall, to withstand all external mold weight, jack oil return leave concrete surface at the same time, external mold to metope, correction verticality colligation steel bar, and start using the reserved hole mould. Explosion-proof electric hoist the exposed explosion-proof parts of the hoist are made of special non-spark materials, and the explosion-proof performance is safe and reliable. Products through the ministry of machinery industry explosion-proof electrical products quality supervision and inspection center Jiamusi sub-center explosion-proof performance testing, and issued explosion-proof certificate.