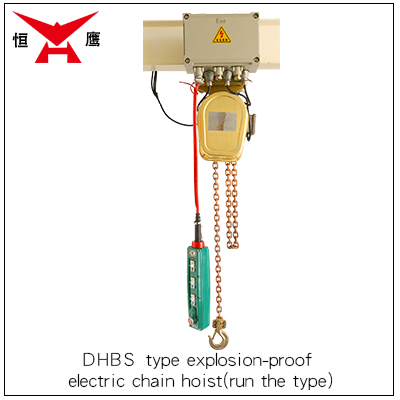

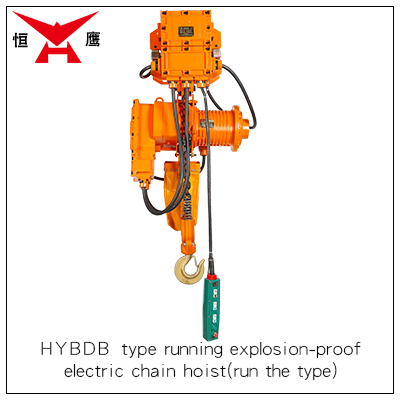

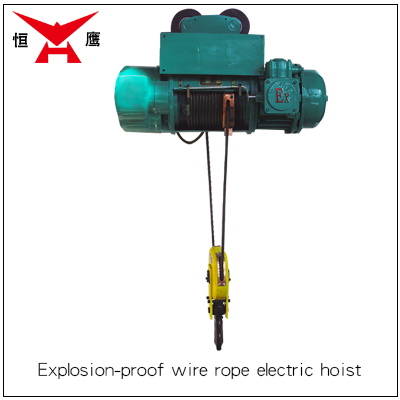

Explosion-proof electric hoist in outdoor operation for a long time, not from the impact of weather and environmental changes, and for metal equipment, once there is no corresponding protection measures, it is easy to rust and other problems, thus affecting the construction progress and safety, so how do we avoid the occurrence of this situation? By hengying lifting belt you easily solve!

To solve the corrosion problem of explosion-proof electric hoist, it is very important to do the corresponding protection work. In order to ensure the use in a reliable environment, the construction should first understand the recent weather conditions, to see whether there is rain and snow weather, so as to prepare and protect the work in advance, try to avoid these periods, so that the project is completed in advance or delayed completion, during the rain and snow arrangements for other work, in order to ensure the overall progress of the project.

In addition, after the equipment is used for a long time, in order to avoid rust and ensure the good performance of the explosion-proof electric hoist, before each operation, it should also be smeated at the cracks of the operating mechanism parts with anti-rust grease, and do a good job of lubrication. After the operation, it is necessary to wipe the water droplets on the surface of the equipment in time to ensure that the oil is dry and then coated with grease. If conditions are available, a layer of rain cover can be covered, which not only avoids the invasion of wet air and rain, but also can prevent some rust even if accidentally immersed in water.

The above is to solve some methods of explosion-proof electric hoist corrosion, preventive maintenance in advance can make the equipment get better use. Hengying crane has been committed to the production of lifting equipment, welcome new and old customers to consult and buy.