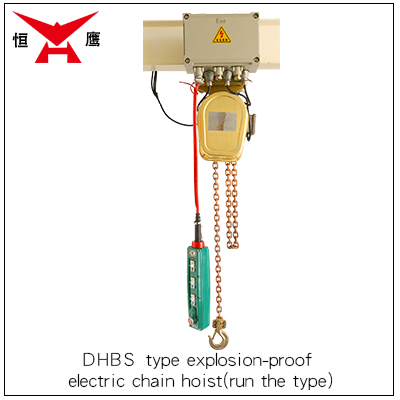

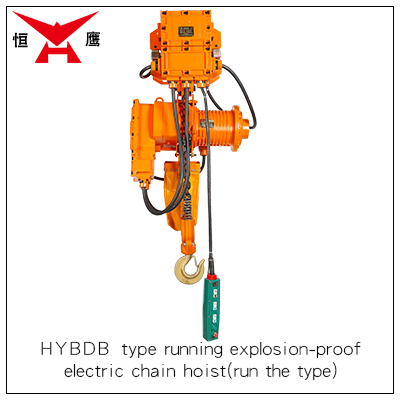

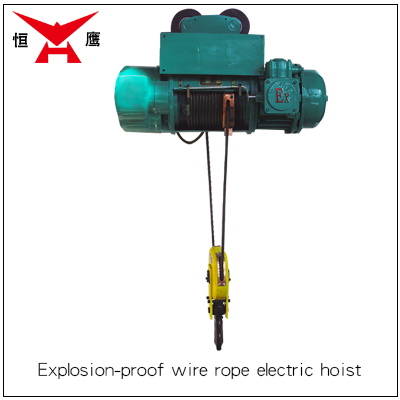

Explosion-proof hand pull hoist can be widely used in petroleum, petrochemical, oil depot, gas, chemical, military, power, mining, electronics, railway and other potential fire and explosion dangerous environment, in the operation of the product friction collision will not produce mechanical sparks, effectively prevent fire accidents, to ensure national property and personal safety. Safety elements of explosion-proof hand hoist are as follows:

1, explosion-proof hand hoist lifting chain should be suspended vertically, there shall be no wrong twist of the chain, the lower hook frame of the double chain shall not be overturned. The operator should stand in the same plane as the hand sprocket pull the hand chain, so that the hand sprocket along the clockwise rotation, the weight can rise; Reverse pull hand chain, can slowly descend. When lifting heavy objects, it is strictly prohibited to do any work or walk under them to avoid personal accidents.

2, explosion-proof hand hoist in the process of lifting, no matter the weight rises or falls, pull the hand chain, the force should be uniform and slow, do not force too hard, so as not to beat the hand chain or clasp. If the operator finds that the hand tension is greater than the normal tension, should stop using immediately. Maintenance: After use, the gourd should be cleaned and coated with anti-rust grease, and stored in a dry place. The maintenance and overhaul should be carried out by those who are familiar with the hoist mechanism, so as to prevent those who do not understand the performance principle of the machine from disassembling and assembling at will.

3. Overloading is strictly prohibited, and other power operation is strictly prohibited. Before use, make sure that the parts are intact, the transmission part and the lifting chain are well lubricated, and the idling condition is normal. Check whether the upper and lower hooks are fastened before lifting. Heavy objects hanging on the tip are strictly prohibited.

4, explosion-proof hand hoist after cleaning and maintenance, should be no-load test, confirm normal work, reliable braking, can be delivered to use. The friction surface of the brake must be kept clean, and the brake part should be checked frequently to prevent brake failure and self-falling phenomenon.