How is the installation and debugging of explosion-proof electric hoist? Everybody know? Do not know can be understood in the following article!

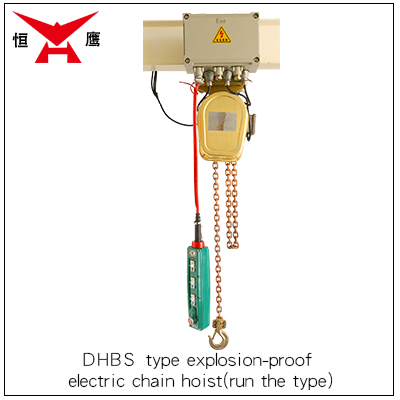

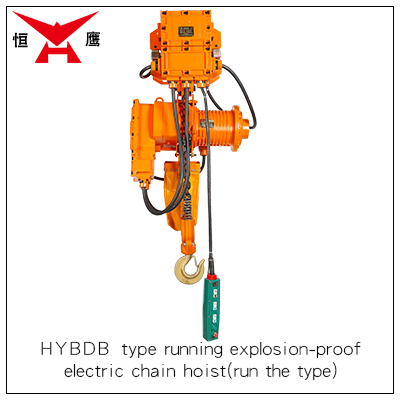

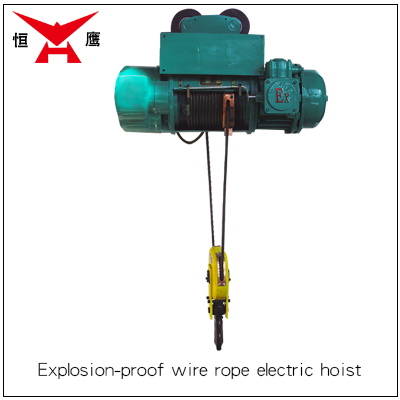

First of all, check the host, operating mechanism, control appliances (cable, buckle box, wiring frame) of the electric hoist is complete, installation environment (mine, chemical plant, pharmaceutical factory, port, gas pipeline, tunnel), track model is matched.

Secondly, on the ground, the host of the explosion-proof electric hoist is installed on the main girder, and fine adjustment is carried out. The spacing between the inner flange of the equipment and the flange of the single beam track meets the technical requirements (see the manual). The installation of the power line, slide line and bracket should be standardized.

Then, the electrical control box, slide wire, cable and so on according to the requirements of electric hoist wire rope technical specification installation.

In addition, remember to run after the installation, test the up, down, left, right operation is normal.

Debugging of explosion-proof electric hoist:

In the test process, wire rope electric hoist must be carried out in accordance with the requirements of special equipment safety technical regulations for empty load, static load, dynamic load test.

Electric hoist explosion-proof mark is D ⅱ BT4, D ⅱ CT4, suitable for grade ⅱ A, ⅱ B, ⅱ C, T4 group temperature is RESPECTIVELY T1 - T4 combustible gas, steam and air to form explosive gas mixture place.

Explosion-proof electric hoist in the process of operation, it is forbidden to cable pull, overload, no hanging, no standing under the machine.

The above is four explosion-proof electric hoist how to install and debug some of the content, you can understand, what problems and needs, you can directly leave a message on the website your contact information, we will contact you in time!